ige filetée zn 5.8 / hdg 5.8 m24 x 210: Superior Strength

Have you ever wondered what the mysterious term “ige filetée zn 5.8 / hdg 5.8 m24 x 210” means? If you’re involved in construction, engineering, or manufacturing, chances are you’ve come across this phrase. Let’s delve into the details and uncover the significance of this product.

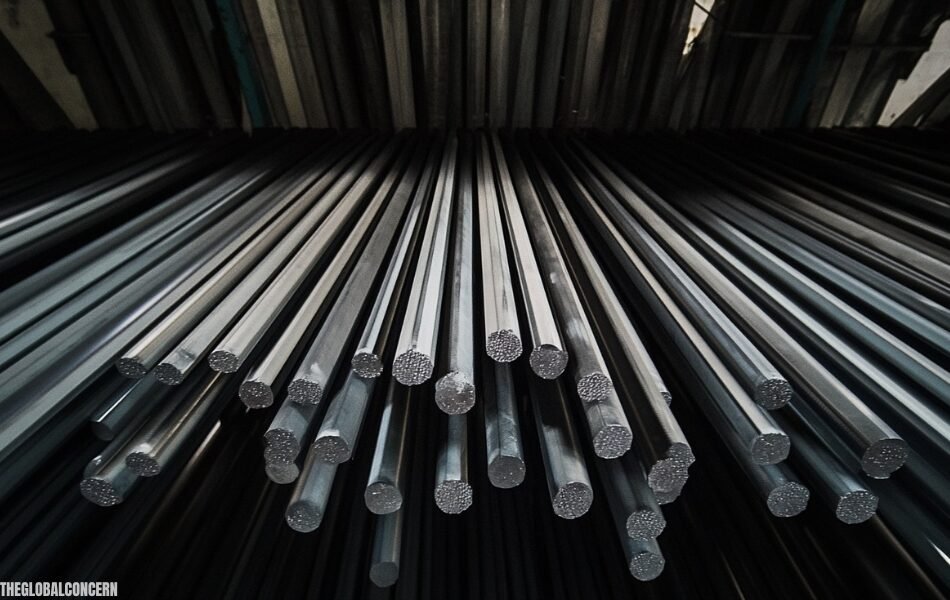

At its core, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” refers to a specific type of threaded steel rod. The terms “ige filetée” and “hdg 5.8” denote the threading pattern and hot-dip galvanized coating, respectively. “M24” indicates the diameter of the rod, while “210” refers to its yield strength.

A Deeper Dive into “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

Understanding the Components

“ige filetée” refers to the specific threading pattern used on the steel rod. The “ige” prefix denotes a particular type of thread profile, while “filetée” means “threaded” in French. “zn 5.8” indicates the zinc coating applied to the steel rod, with “zn” signifying zinc and “5.8” referring to the minimum average thickness of the zinc coating in microns. This coating provides excellent corrosion resistance, making the rod suitable for outdoor applications and environments with high humidity.

“hdg 5.8” is another term for the zinc coating process, specifically hot-dip galvanizing. In this process, the steel rod is immersed in molten zinc, resulting in a thick, uniform coating that adheres strongly to the base metal. “m24” represents the diameter of the steel rod in millimeters, indicating a relatively thick rod suitable for applications requiring significant strength and load-bearing capacity. “210” refers to the yield strength of the steel used in the rod, which is the maximum stress a material can withstand before it starts to deform permanently.

Material Composition and Manufacturing

The steel rod used in “ige filetée zn 5.8 / hdg 5.8 m24 x 210” is typically made from carbon steel, a common type of steel known for its strength and versatility. The specific composition of the steel may vary slightly depending on the manufacturer, but it will generally contain a combination of iron, carbon, and other alloying elements.

The manufacturing process for this product involves several steps:

- Steel Rod Production: The steel is melted in a furnace and poured into a mold to create the desired shape and size of the rod.

- Threading: The threaded pattern is cut onto the surface of the rod using specialized machinery.

- Zinc Coating: The rod is then immersed in molten zinc to apply the protective coating.

- Quality Control: The finished product is inspected to ensure it meets the specified standards for dimensions, threading accuracy, and coating quality.

Key Specifications and Features of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

Dimensions: While the exact length can vary depending on specific requirements, a standard “ige filetée zn 5.8 / hdg 5.8 m24 x 210” rod typically measures 6 meters in length. The diameter, as indicated by “m24,” is 24 millimeters. The thickness of the rod will depend on its specific application and manufacturing standards.

Strength and Durability: One of the primary advantages of “ige filetée zn 5.8 / hdg 5.8 m24 x 210” is its exceptional strength and durability. The high-quality steel used in its construction, combined with the hot-dip galvanized coating, ensures that it can withstand significant loads and harsh environmental conditions. The yield strength of 210 indicates its ability to resist deformation under stress, making it suitable for demanding applications.

Weight: The weight of an “ige filetée zn 5.8 / hdg 5.8 m24 x 210” rod will depend on its length and any additional coatings or treatments applied. However, as a general estimate, a 6-meter long rod with a diameter of 24 millimeters and a standard zinc coating can weigh approximately 18 kilograms.

Other Features: In addition to its strength, durability, and dimensions, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” offers several other key features:

The specific thread profile used on the rod (ige filetée) is designed to provide a secure and reliable connection when threaded into components. The hot-dip galvanized coating not only protects the steel from corrosion but also enhances its appearance and provides a barrier against environmental factors. The combination of strength, durability, and corrosion resistance makes this rod suitable for a wide range of applications, including construction, engineering, and manufacturing.

Applications and Use Cases of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

The product “ige filetée zn 5.8 / hdg 5.8 m24 x 210” is a flexible and adaptable material used in various construction projects. It is commonly used in structural steelwork, reinforcing structural steel frames, beams, and columns. It can also be used to anchor heavy equipment, machinery, and fixtures to concrete or masonry structures. The product’s corrosion resistance is essential for bridge components exposed to harsh weather conditions, and it is used in the construction of industrial facilities, warehouses, and factories to provide structural support.

In various engineering fields, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” has diverse applications. It is used in the construction of machinery components, such as shafts, axles, and connecting rods, in mechanical engineering. In civil engineering, the rod’s strength and durability make it suitable for infrastructure projects, including roads, railways, and tunnels. It is also used in the design and construction of structures, such as buildings, bridges, and towers, in structural engineering.

In manufacturing processes, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” is used to create components for various types of machinery, including industrial equipment, agricultural machinery, and construction equipment. It is also used to fasten and secure different parts of machinery and equipment, and can be used in various manufacturing processes, such as welding, assembly, and fabrication.

Beyond construction, engineering, and manufacturing, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” has applications in other industries, including shipbuilding and marine construction, oil and gas, and telecommunications.

Benefits and Advantages of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

Cost-Effectiveness:The product “ige filetée zn 5.8 / hdg 5.8 m24 x 210” provides exceptional value for its cost. The combination of high-quality materials, durable construction, and long lifespan makes it a cost-effective choice for various applications. Its durability ensures that it will last for many years, reducing the need for frequent replacements and maintenance.

Durability: The product’s durability is a significant advantage. The hot-dip galvanized coating provides exceptional protection against corrosion, ensuring that the rod remains strong and functional even in harsh environments. The high-quality steel used in its construction further enhances its durability, making it resistant to wear and tear.

Safety: While “ige filetée zn 5.8 / hdg 5.8 m24 x 210” does not have specific safety features, its strength and durability contribute to overall safety. When used correctly and installed properly, it provides a reliable and secure solution for various applications.

Environmental Impact: While the product itself does not have a direct positive environmental impact, its durability and long lifespan can contribute to environmental sustainability. By reducing the need for frequent replacements, it helps to minimize waste and conserve resources. Additionally, the zinc coating provides corrosion protection, reducing the need for maintenance and repairs that can have environmental consequences.

Installation and Usage of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

While specific installation and usage guidelines may vary depending on the application and project requirements, here are some general recommendations:

Ensure that the surface to which the rod will be attached is clean, free of debris, and properly prepared. If necessary, cut the rod to the desired length using a suitable cutting tool, such as a hacksaw or angle grinder. If threading is required, use appropriate threading tools to create the necessary threads on the rod. Secure the rod in place using appropriate fasteners, such as nuts and bolts. Ensure that the connections are tight and secure.

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing, when handling or installing the rod. Use proper lifting techniques and avoid lifting heavy loads alone. Handle cutting and threading tools with care to prevent injuries. If working in areas with electrical equipment, take necessary precautions to avoid electrical shocks.

Inspect the rod periodically for signs of wear, corrosion, or damage.Make sure all connections are firm and secure. If the zinc coating is damaged, consider repainting the rod to maintain corrosion protection. When storing the rod, keep it in a dry, clean environment to prevent rust and corrosion.

By following these guidelines and taking necessary safety precautions, you can ensure the proper installation, use, and maintenance of “ige filetée zn 5.8 / hdg 5.8 m24 x 210” for your specific application.

Pricing and Availability of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”

The cost of “ige filetée zn 5.8 / hdg 5.8 m24 x 210” can fluctuate due to factors such as length, quantity, vendor, and prevailing market circumstances. While it’s difficult to provide an exact price range without specific information, you can expect to pay a competitive price for this high-quality product. It’s recommended to compare prices from various vendors to obtain the most favorable offer.

The product “ige filetée zn 5.8 / hdg 5.8 m24 x 210” can be easily obtained from various sources, such as online retailers, hardware stores, construction supply stores, and manufacturers. While it’s difficult to compare the price and availability of this product to exact equivalents, you can compare it to other threaded steel rods with similar specifications. Consider factors such as the diameter, length, coating type, and yield strength. Additionally, compare the prices offered by different suppliers to find the best deal.

By carefully considering these factors, you can make an informed decision when purchasing “ige filetée zn 5.8 / hdg 5.8 m24 x 210” and ensure that you get the best value for your money.

Conclusion

“ige filetée zn 5.8 / hdg 5.8 m24 x 210” is a versatile and durable threaded steel rod that offers numerous benefits for various applications. Its exceptional strength, corrosion resistance, and versatility make it a valuable asset in construction, engineering, and manufacturing industries.

By understanding the key specifications, features, applications, and benefits of this product, you can make informed decisions when selecting the right steel rod for your projects. Whether you’re building a structure, assembling machinery, or working on infrastructure projects, “ige filetée zn 5.8 / hdg 5.8 m24 x 210” can provide a reliable and effective solution.

We encourage you to research suppliers to find the best pricing and availability options, consult with experts if you have specific questions or require professional advice, and share this article with others who may benefit from understanding the value of “ige filetée zn 5.8 / hdg 5.8 m24 x 210.” By taking these steps, you can make the most of this valuable product and ensure its effective use in your projects.

FAQ’s

Q: What is “ige filetée zn 5.8 / hdg 5.8 m24 x 210”?

A: “ige filetée zn 5.8 / hdg 5.8 m24 x 210” refers to a specific type of threaded steel rod. The terms “ige filetée” and “hdg 5.8” denote the threading pattern and hot-dip galvanized coating, respectively. “M24” indicates the diameter of the rod, while “210” refers to its yield strength.

Q: What are the common applications of “ige filetée zn 5.8 / hdg 5.8 m24 x 210”?

A: “ige filetée zn 5.8 / hdg 5.8 m24 x 210” has diverse applications in construction, engineering, and manufacturing. It is used in structural steelwork, anchoring and fastening, bridge construction, industrial buildings, machinery fabrication, equipment assembly, manufacturing processes, marine, oil and gas, and telecommunications.

Q: What is the typical price range for “ige filetée zn 5.8 / hdg 5.8 m24 x 210”?

A: The price can vary depending on factors such as length, quantity, supplier, and market conditions. However, you can expect to pay a competitive price for this high-quality product. Comparing prices from different suppliers is recommended.

Q: Where can I purchase “ige filetée zn 5.8 / hdg 5.8 m24 x 210”?

A: You can purchase “ige filetée zn 5.8 / hdg 5.8 m24 x 210” from various sources, including online retailers, hardware stores, construction supply stores, and manufacturers.